NYC Lead Removal Contractors-- Get Safe and Reliable Services

NYC Lead Removal Contractors-- Get Safe and Reliable Services

Blog Article

Crucial Tools and Approaches for Effective Lead Infraction Cleanup

Dealing with lead infractions efficiently necessitates a detailed approach that blends the right tools with tactical techniques. Concurrently, the use of specialized clean-up devices, such as HEPA vacuum cleaners and lead-specific cleansing representatives, is vital for detailed impurity removal. Reliable containment methods, including plastic sheeting and negative air stress systems, are essential to prevent the spread of harmful materials.

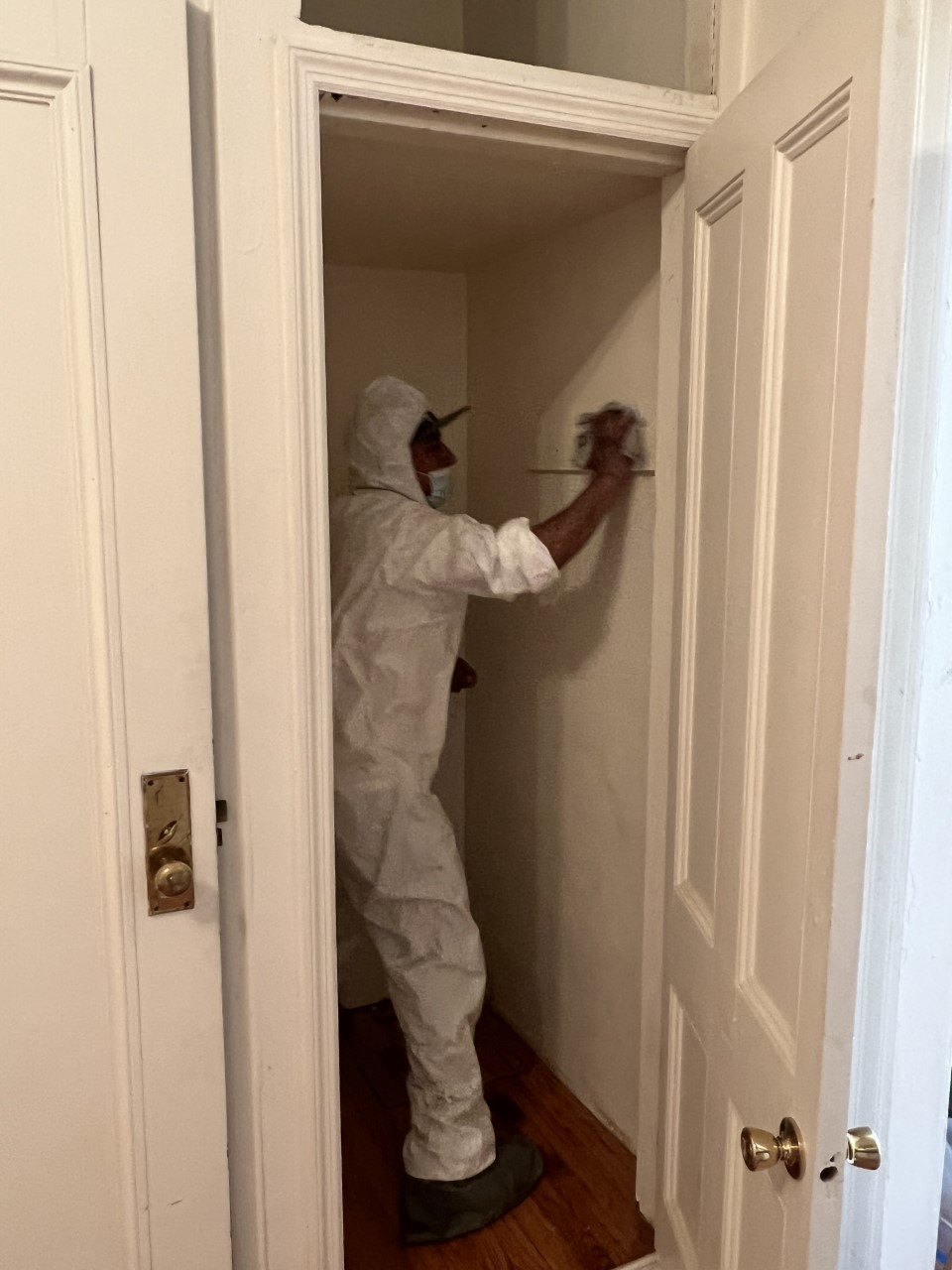

Personal Safety Equipment

Individual safety tools (PPE) is a vital component in the efficient monitoring of lead contamination cleaning. PPE works as a vital barrier, guarding workers from the hazardous effects of lead exposure, which can result in extreme wellness repercussions. The important PPE for lead clean-up includes respirators, protective clothing, gloves, and eye security. Each sort of devices is especially made to alleviate different threats related to lead particles and dust.

Respirators, especially those geared up with HEPA filters, are important for filtering system airborne lead bits, stopping breathing. Protective garments, consisting of coveralls and disposable matches, stops lead dirt from adhering to employees' garments, decreasing the threat of secondary contamination.

In addition, strenuous training on the proper usage and maintenance of PPE is necessary. Workers need to be informed on donning and doffing treatments to stay clear of contamination. Regular examinations and substitutes of PPE components are essential to preserve their protective capabilities, making sure a secure and compliant cleaning procedure.

Specialized Clean-up Equipment

One more necessary device is the wet/dry vacuum cleaner, which can properly cleanse up both dirt and liquid pollutants. These vacuums usually include HEPA filters to provide an added layer of safety. Wet cleans or tack towels are also crucial for surface area cleaning; they are especially designed to catch and hold lead particles, minimizing the risk of spreading out contamination.

For more persistent deposits, specialized lead-removal cleansing representatives are needed. These representatives are created to damage down lead particles, making them much easier to remove. Scrub brushes with strong bristles can assist in this procedure, especially on harsh surfaces where lead dirt often tends to stick extra highly.

In addition, encapsulants are used to secure lead-contaminated surfaces, avoiding the release of lead dust. These specialized paints and finishings are made to abide by various substratums, supplying a lasting service for lead containment.

Efficient Containment Methods

Efficient control approaches are critical in reducing the spread of lead contamination throughout cleaning activities. Applying robust containment approaches makes sure that lead fragments do not migrate to untouched areas, therefore shielding both workers and the atmosphere (DOH & HPD Lead Violation Removal NYC).

To boost control, encapsulants can be related to surfaces that are not being gotten rid of or disturbed. These specialized finishings bind lead dust, decreasing its accessibility for resuspension. Furthermore, Home Page all workers need to use suitable Personal Protective Tools (PPE), including respirators and non reusable fits, to avoid contamination spread.

Safe Disposal Practices

Guaranteeing secure disposal techniques is a crucial element in the administration of lead contamination clean-up. Proper disposal alleviates the threat of lead re-entering the atmosphere and endangering public wellness. The primary step is to recognize and set apart lead-contaminated waste from other products. Safe containment making use of sturdy, leak-proof containers is important to stop spillage throughout transport.

Transporting lead waste requires adherence to strict standards. Using qualified harmful waste carriers makes sure that the materials are handled sensibly. Documents, consisting of manifests describing the type and amount of waste, need to come with shipments to track the waste from the website of origin to its last disposal destination.

Designated contaminated materials disposal facilities are geared up to take care of lead-contaminated materials safely. These centers often use innovative approaches such as stablizing, solidification, or chemical treatment to neutralize the lead before disposal. Landfilling in specialized, lined locations that stop leachate from infecting groundwater is an usual method for last disposal.

Normal training for workers entailed in lead garbage disposal is crucial to maintain security requirements and stop accidental exposure. By adhering to these practices, companies can substantially minimize the ecological and wellness effects connected with lead contamination.

Regulatory Conformity Tips

Sticking to regulative compliance is critical in the successful implementation of lead contamination clean-up. Understanding and complying with federal, state, and local guidelines makes sure not just the security and health and wellness of individuals yet also the legal important link and economic well-being of the cleanup organization. The Environmental Defense Firm (EPA) sets stringent standards, such as the Lead Improvement, Fixing, and Painting (RRP) Policy, which mandates proper accreditation and training for specialists handling lead-based tasks.

Compliance starts with an extensive analysis of relevant legislations and policies. Organizations has to stay upgraded on any type of legislative changes, which can be promoted via normal training sessions and subscribing to sector updates. Paperwork is one more crucial compliance element; preserving comprehensive documents of all tasks, consisting of examination reports, staff member training logs, and disposal materializes, is important.

In addition, engaging with licensed lead examiners or risk assessors ensures that lead dangers are properly recognized and reduced. Companies have to apply using Individual Safety Devices (PPE) and make certain that safety and security procedures are purely adhered to. Clear communication with stakeholders, consisting of workers, clients, and governing bodies, will cultivate a society of compliance and accountability, ultimately contributing to a more secure and a lot more efficient lead clean-up process.

Conclusion

Efficient lead violation clean-up necessitates the combination of specialized devices and critical methodologies to ensure safety and efficiency. Using HEPA vacuum cleaners, specialized cleansing agents, and effective read review containment approaches such as plastic sheeting and adverse air stress systems is crucial. Personal safety equipment (PPE) safeguards employees from exposure, while secure disposal practices and stringent adherence to regulative conformity are vital for sensibly taking care of dangerous waste. Jointly, these measures dramatically alleviate health risks and contribute to a cleaner setting.

Report this page